Powder metallurgy has become a significant factor in contemporary manufacturing. The demand for precision parts, sustainable production processes and cost-effective techniques are causing an industrial revolution. In contrast to traditional metalworking techniques, like cutting, casting, or forging metal, powder metallurgy involves the pressing of metal powders and condensed into complex components that are high-performance. This process is not just fast, but it also gives designers new design options that were previously unattainable or complicated using conventional machining.

Powder metallurgy is now a necessity for a range of industries including aerospace and automotive to energy, electronics as well as medical technology. Its capability to make complex, robust and almost-net-shaped components helps manufacturers decrease waste and enhance the consistency of their products. This method is especially suited to today’s fast-paced, high-volume production environments where both performance and precision are non-negotiable.

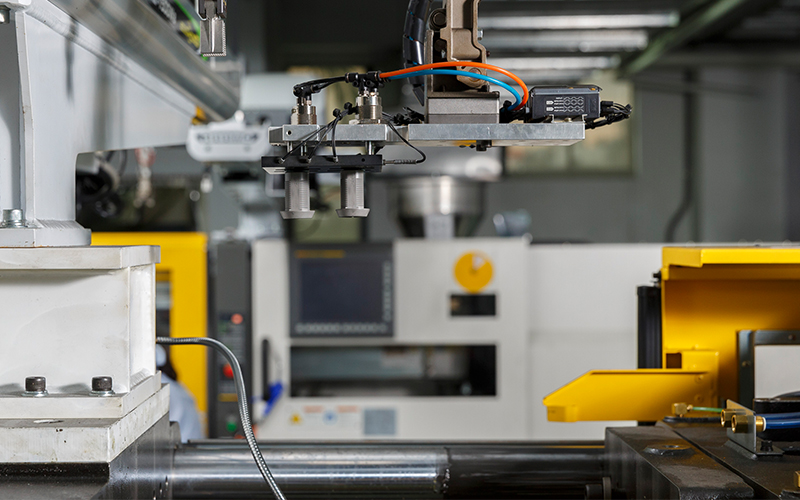

Image credit: tw.porite.com

Taiwan Porite Leads the Powder Metallurgy Industry

In the global leader list in this field, Porite Taiwan stands out as a significant force. Being a founding part of the Porite Group, Porite Taiwan makes up nearly 50% of the group’s global output. Recognized as one of the top powder metallurgy manufacturers in the world, the company brings decades of engineering expertise, advanced technology, and strict quality control to every product it creates. The company’s products are used in a myriad of different applications such as motor vehicles, household appliances aircraft, electrical devices, aviation and new green energy technologies.

The manufacturing expertise of Porite lies in its ability meet complex large-scale demands, while making sure that each part is in compliance with the strict standards of international quality. The extensive experience in the sintering process, metallurgy and other techniques allows it to design solutions that are specifically designed for very specific industry requirements. Porite’s name has been built on trust and precision, which are important attributes in today’s competitive global market.

Metal Injection Molding and Precision Manufacturing

While powder metallurgy provides the base, metal injection molding companies represent an advanced extension of this technique. Metal injection molding (MIM) blends fine metal powders with binder to produce a moldable feedstock, which is then in a mold similar to plastic injection molding. The binder is then removed, and the part is then sintered for final durability and strength.

This process permits the development of extremely complex metal components with tight tolerances and superior mechanical properties. MIM’s capacity to manufacture tiny, precise components in large quantities makes it a popular choice for various industries, including consumer goods, medical devices electronic equipment, and defense. MIM’s capability to blend highly-performing metals and intricate geometries makes it a powerful tool for product development. Metal injection molding companies are focused on flexibility, innovation and sustainability to satisfy changing demands of their customers.

Filters made of sintered metal: a quiet but critical component

One of the most important but often undervalued applications of powdermetallurgy is to create sintered metal filters. They are made with the same pressing and sintering techniques but are designed to be porous and allow liquids and gases to pass through while trapping impurities. A reputable sintered metal filter maker will ensure that the filters perform under extreme conditions such as extreme temperatures, high pressures or environments that are corrosive, without compromising their integrity or effectiveness.

Sintered metal filters are widely employed in various industries, including food processing, pharmaceuticals, petrochemicals processing, and clean energy. They can provide reliable filtering, long-lasting service, and low maintenance, making them essential to any operation where precision and safety are vital.

Powder Metallurgy is a Future-Ready Manufacturing Solution

Powder metallurgy is playing an increasing role in the global manufacturing landscape evolves. The powder metallurgy’s mix of flexible design, material efficiency and scalable production makes it an attractive option for industries confronting rising costs, tighter regulations, and a heightened level of competition.

The entire powder metallurgy system is driving innovation, redefining metal manufacturing. From the most advanced injection molding companies to reliable manufacturers of sintered metal filters, this industry is transforming the metal manufacturing industry. Porite Taiwan, a leader in the industry and setting the bar for international standards. The future of precision metal parts is being formed and pressed every day.