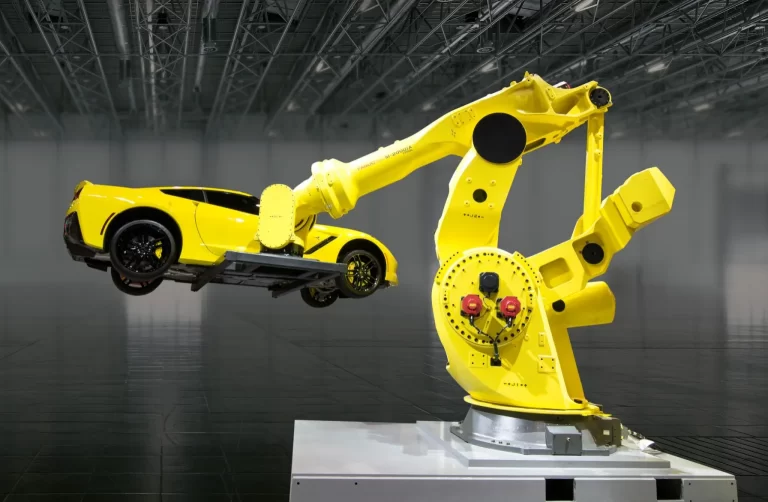

Robotic arms are at the core of modern manufacturing and production have changed the rules in a way that was previously not possible. They bring precision, safety and efficiency. These technological marvels, sometimes referred to as robot arms, have become indispensable in many industries around the world and are driven by the imperative need to reduce operating costs and maintain high standards of quality. Robotic arms are being incorporated into production lines to cut cost and increase security. Learn how these cutting-edge machines have transformed the industrial landscape.

Image credit: automatedsolutions.com.au

The primary force behind the rapid growth in robotic arm usage is the efficiency of costs. Factories are under constant pressure to minimize production errors, reduce the amount of waste and reduce work-related accidents. Robotic arms address these issues head-on. Robots are more precise than human beings when performing repetitive tasks, thus reducing cost and eliminating costly mistakes. In industries with high volumes, such as automotive manufacturing, robot arms guarantee perfect assembly through precise welding and parts positioning. This precision could translate into substantial savings since less defective items mean less work or waste.

The security of robotic arms is an important aspect. There are many manufacturing processes that require handling dangerous materials or operating large machinery pose risks for human workers. Robots allow businesses to get their workers out of dangerous surroundings and decrease workplace injuries. Robotic arms consist of a variety of movable joints that mimic the human arm’s capabilities. They can however operate without danger of injuries. Equipped with end effectors that can be programmed to work essentially robotic hands they can perform tasks like grasping, spinning or welding in situations which are dangerous for human beings.

The versatility of robotic arms makes them a game-changer across diverse industries. Robot arms can handle different tasks. From assembly of automobiles, to electronic production. The ability to program these arms allows them to perform complicated operations such as painting or applying fiberglass at an unmatched quality of consistency. In the field of warehousing, robot arms have changed palletizing by automating the process of loading products onto pallets using precision and speed. Automation not only increases efficiency however, it also improves reliability because robot arms can be productive without fatigue.

The development of cobots (collaborative robots) that interact with human employees is among of the most thrilling innovations in the field. Cobots, which are equipped with a robotic arm, are able to communicate with humans seamlessly unlike industrial robots that are typically restricted to cells. The robotic hand of a cobot can be utilized for routine tasks like heavy lifting in factories, so that human workers are freed up to handle more complex tasks. The robots can stop or change their movement in the event that they spot a worker near.

The impact of robotic arms goes beyond safety and efficiency to the very fabric of modern manufacturing. Their capability to complete tasks like welding assembly, assembly, or even handling materials with precision has made them indispensable in high-risk industries. For instance, in automotive manufacturing, a robotic arm is able to rotate and move parts during assembly, ensuring an exact alignment with no human intervention. In the electronics industry, robots are used to handle delicate components, which reduces damages and improves the quality of output.

As industries continue to evolve, the role of robotic arms will only grow. They will be a key element in the future of manufacturing due to their ability to lower costs, enhance security and adapt to various tasks. Through the combination of cutting-edge technology and human creativity, robot arms are not only tools, they are partners in progress, driving innovation and revolutionizing how we construct the world around us.